Subcontracting

Subcontracting

Your parts have at least one flat surface, you want to guarantee flatness, parallelism between the faces, thickness and surface finish, it is our job.

We work on :

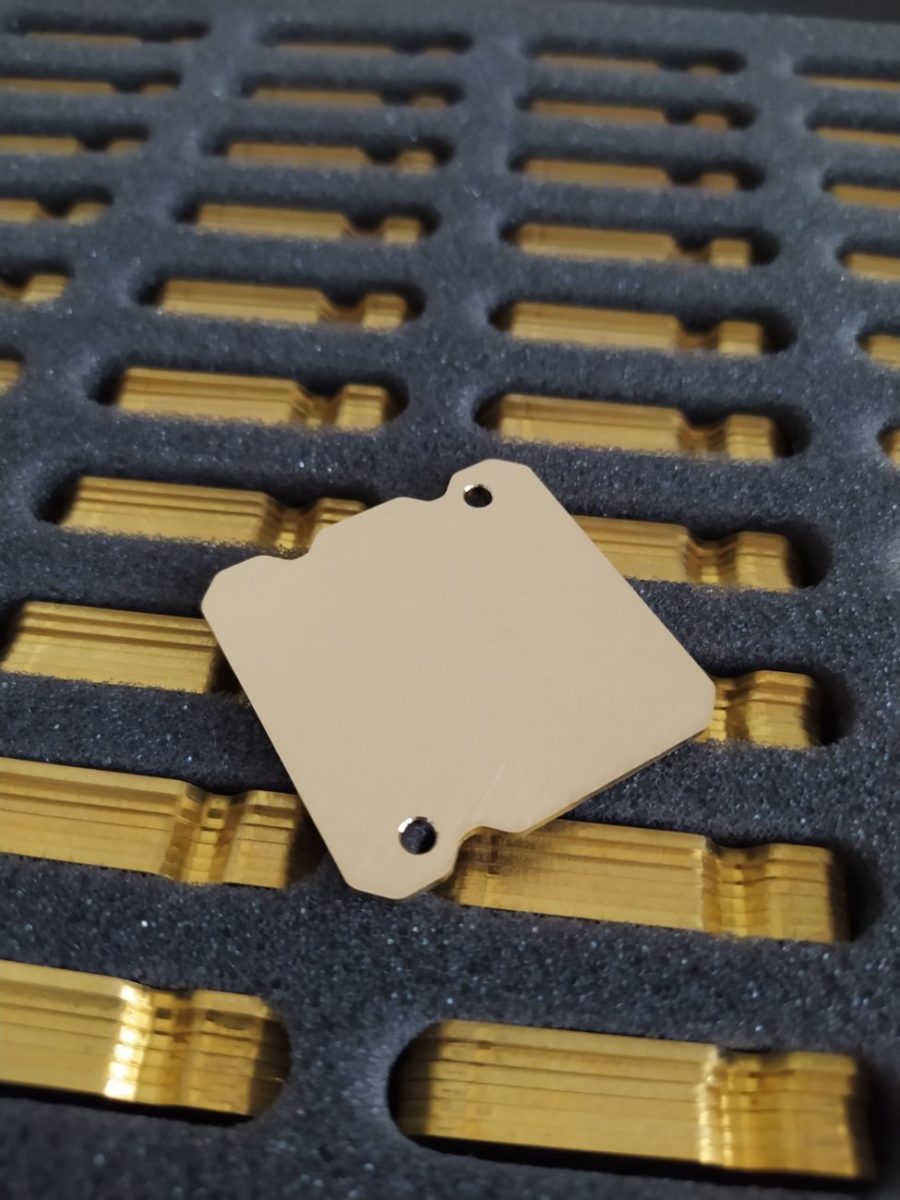

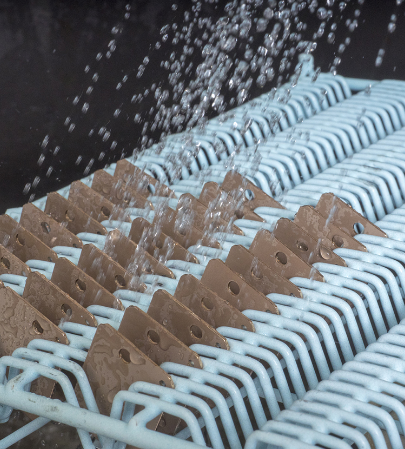

- All types of parts: trays, washers, plates, bridges, windows, wafers, links, insulators, etc.

- In all rigid materials: metals, ceramics, crystals, glasses, natural materials, composites, etc. Down to very thin thicknesses of 0.10 mm

- For all fieldss of activity: watchmaking, optics, medical, electronics, mechanics, etc.

We also provide final polishing, superfinishing or flat black polishing (“Poli Bloqué Noir”) of flat surfaces on all types of parts: bridges, wheels, balance wheels, screws, dials, ratchets, hands, glasses, windows, wafers, indexes, etc.

PBMC works as a subcontractor on all types of materials for thickness setting operations (down to 0.10 mm), polishing and superfinishing (flat black polishing).

Thickening / thinning

This operation consists of removing a certain quantity of material from the parts to bring them to a precise thickness (tolerance in µm). It can be a matter of increasing the thickness of the base material (washers, plates, trays, slips, blanks, etc.) which will then be machined on machines such as milling machines, wire EDM, 5-axis machines. The high dimensional accuracy of the parts taken out of this first operation will facilitate set-up and ensure the quality of machining.

This thinning can also be done on partially or totally machined parts. In this case, in addition to controlling the total thickness, it is possible to separately manage the amount of material removed from each side. This differential removal allows, among other things, to ensure the depth of certain holes or a wall thickness.

In addition to dimensional aspects, lapping or thicknessing done on a double-sided machine allows geometrical aspects, such as flatness and parallelism, to be worked on. In terms of surface finish, it is possible to obtain qualities ranging from lapping (sandblasted appearance) to mirror polish (black blocked polish for watchmakers). Depending on the materials, the roughness descending is of the order of a nanometer, or even less.

Finishing polishing

This operation consists of improving the surface finish of the parts to obtain very low roughness or gloss. The mirror polish, or watchmaker black blocked polish, is this perfect surface where all the micro-scratches disappear to make room for a real mirror. Only experience and mastery of processes can achieve this extreme quality in a reliable and repeatable manner, which we have. The surfaces to be polished sometimes have shallow machining or engravings that must be spared for various reasons:

- Different surface condition at the bottom of the machining (sandblasting, blasting, etc.)

- Keep the edges perpendicular

In other cases, the polished surface should blend seamlessly with a chamfer or chamfer. The part may need a slight rounding on its edges which should be regular. All these requests are possible and achievable on our single-sided machines.

Subcontracting examples

• Thinning of washers and trays (brass, nickel silver, titanium, Durnico, steel, stainless steel, ceramic, carbon, hard metal, gold, platinum, etc.)

• Thinning of amorphous metal specimens (metallic glass)

• Reworking of dials after the stamping operation to restore a geometric reference to the parts.

• Lapping of meteorite washers

• Thinning and polishing of the membrane on sensors (ceramic, stainless steel, etc.)

• Lapping of silicon wafers

• Polishing of enamel dials

• Polishing of components from LIGA manufacturing (Nickel, Nickel Phosphorus)

• Thickness setting of hard metal parts for cutting tools manufacture

• Lapping of rubies

• Polishing of quartz parts to obtain vacuum tightness

• Polishing of carbon parts for mechanical seals

• Thinning and polishing of sapphire parts

• Polishing of glass parts for instrumentation

• Polishing of platinum engraved watch case backs

• Thickness setting of electronics alumina substrates

• Flattening and polishing of tools for manual polishing

• Polishing of movement parts (bridges, ratchets, springs, hammers, etc.)