Lapping - Polishing - Superfinishing

Lapping, polishing, superfinishing

The company

Out of its desire to constantly improve customer service and quality, PBMC SA has pooled together decades of experience in manufacturing and industrialisation of micro-mechanical components, machine design, development of specific tools (fixtures, carriers) and formulating polishing slurries.

We control each step of the process (lapping, polishing, superfinishing) to obtain the requisite geometry and surface finish on your parts.

If you have a new component to polish, you want to improve the quality of your parts or optimise your manufacturing processes, please contact us. We will look at your requirements and objectives together, to implement the optimal solution.

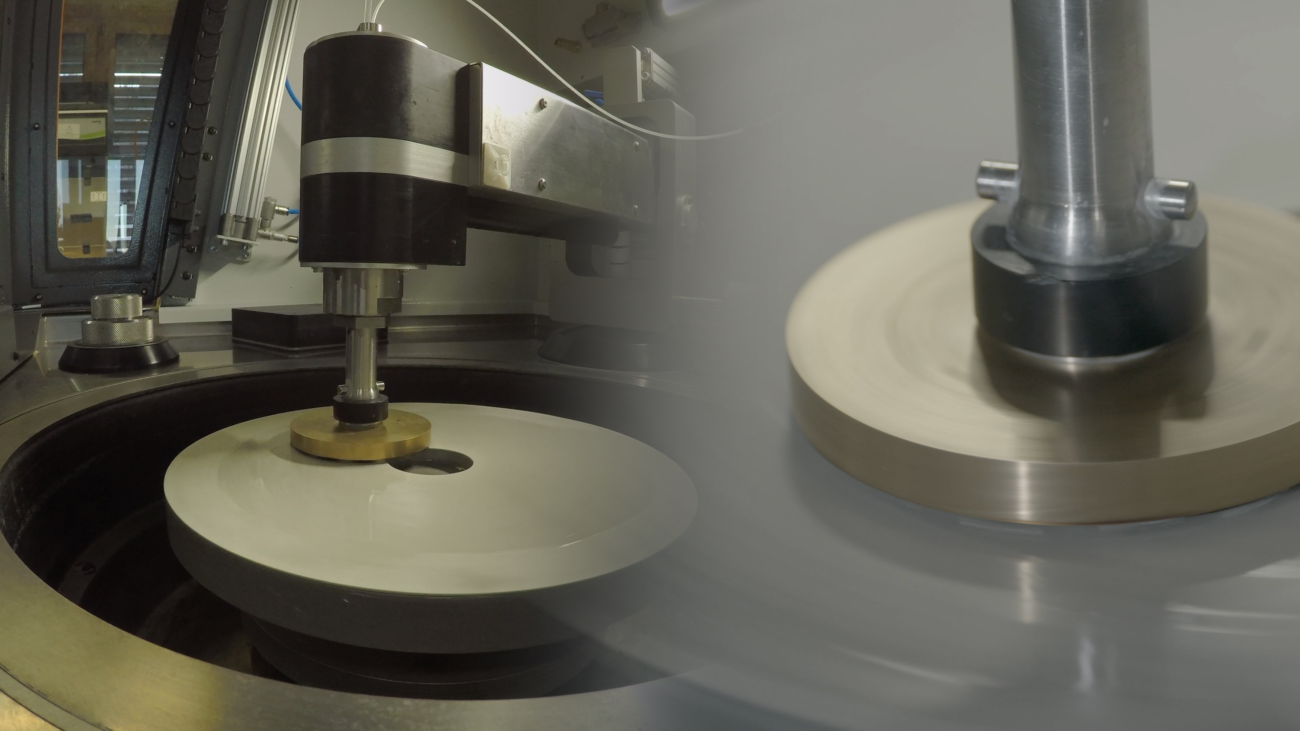

Single-sided lapping, polishing machines manufacture

By virtue of its kinematics and design, our single-sided equipment can obtain perfectly flat surfaces with a remarkable polish quality.

Double-sided lapping, polishing machines manufacture

By virtue of its kinematics and design, our double-sided equipment can obtain perfectly flat and parallel surfaces while controlling the thickness and the surface finish.

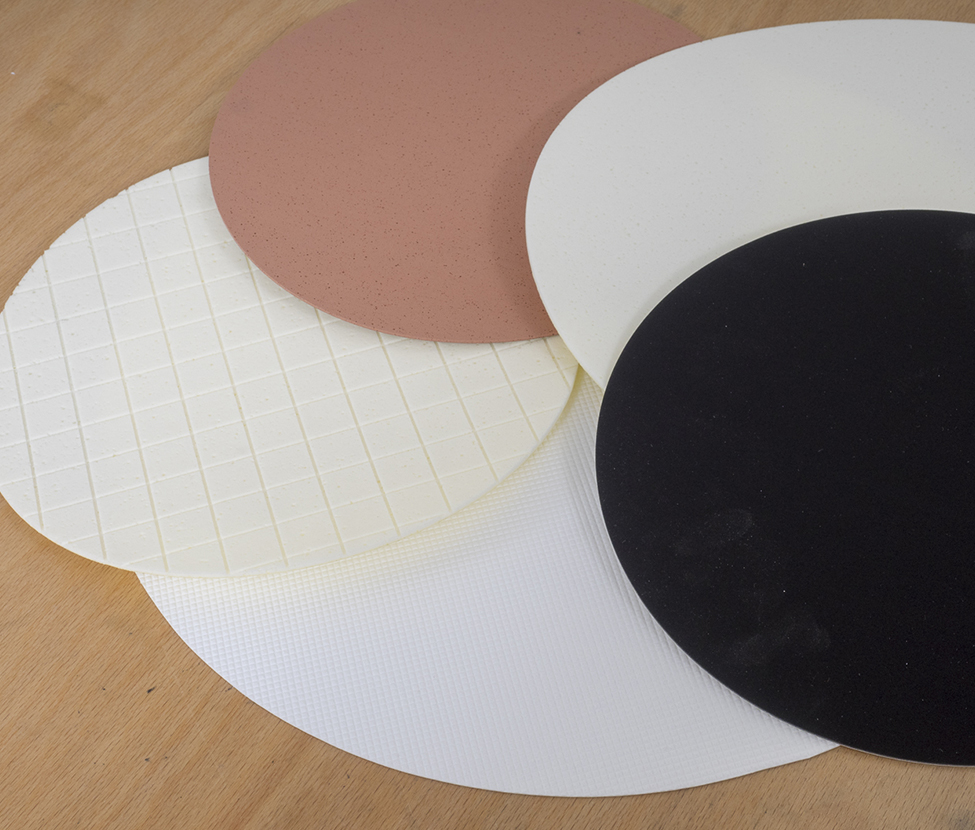

Materials worked

Metals

Steels, Stainless steel, Brass, Nickel silver, CuBe, Titanium, Aluminium, Yellow gold, Pink gold, White gold, Tungsten carbide, Durnico…

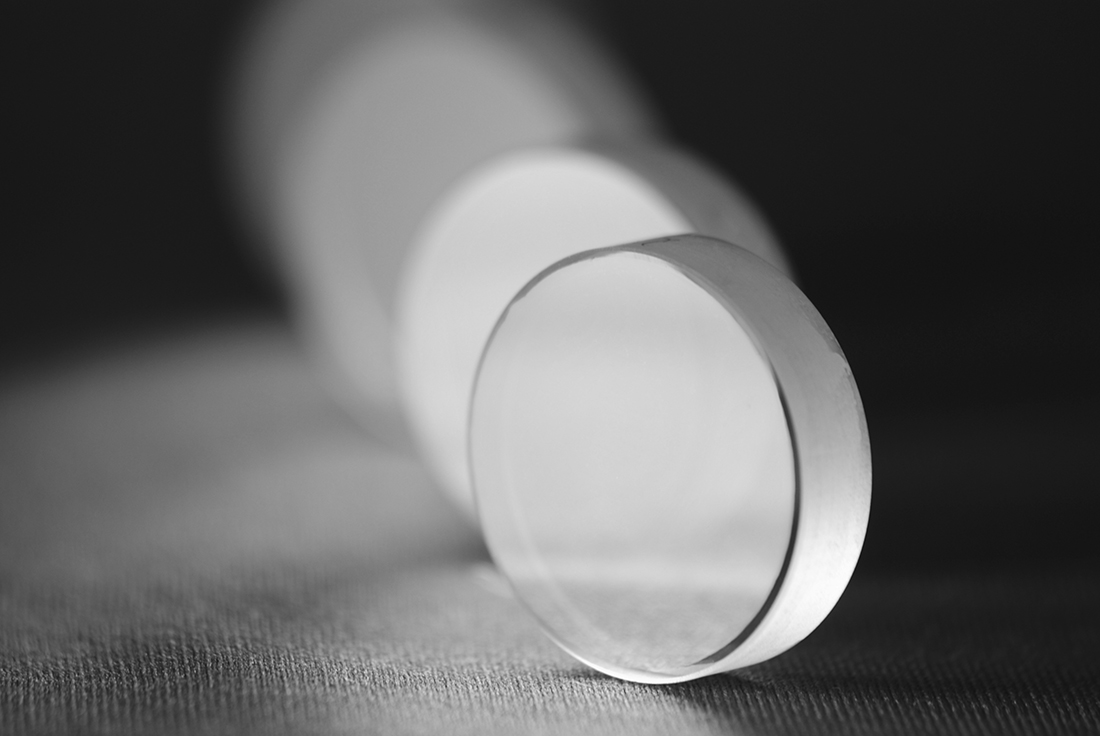

Crystals

Sapphire, Glass, Enamel, Ruby, Quartz, Borosilicate, Vitroceramic…

Ceramics

Al203, Zr02, AlN, Si3N4, Al2Ti05…

Natural materials

Mother-of-pearl, Semi-precious stones (tiger’s eye, lapis lazuli, etc.), Meteorite…

Composites

Carbon fibre, Resin, HyCeram…